NEOSTEER CL

TOOL DETAILS

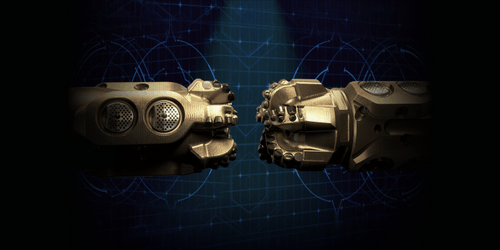

The NeoSteer CL* curve and lateral at-bit steerable system (ABSS) is specifically designed to enable drilling the curve and lateral in a single run. It enables achieving high build rates and extended lateral lengths without compromising ROP. Especially where vertical, curve, and lateral sections are the same hole size, the NeoSteer CL ABSS reduces NPT by eliminating the need to change out the BHA for every section.

The NeoSteer CL ABSS uses piston technology to push against the borehole wall for propulsion; the pistons are placed next to the cutting structure for greater curvature leverage. TheNeoSteer CL ABSS uses this leverage to achieve higher build rates with no additional application of hydraulic force. This provides the ability to meet both the build requirements in the curve section and the directional control requirements in the lateral section.

The NeoSteer CL ABSS steering unit incorporates metal-to-metal hydraulic seals which reduce erosion and increase hydraulic design capability for improved performance. In addition, the ABSS can be adapted with XPC* extreme-profile single shoulder connections to increase reliability during high-DLS drilling. These connectors also enable compatibility with Smith Bits PDC application-specific cutting structures. TheNeoSteer CL ABSS and customizable bits work in concert to provide single-run drilling with greater drilling efficiency.

CURIOUS TO KNOW MORE?

LET’S CHAT

© Extreme 2021, All Rights Reserved. Design by Midnight Marketing LLC